Cyclo® Moto-réducteur avec limiteur de couple

Détectez les surcharges instantanément avec le limiteur de couple intégré

- Moto-réducteur Cyclo® avec limiteur de couple installé pour déterter les surcharges.

- Protège vos précieux unités contre les défaillances catastrophiques.

- La limitation de couple est appliquée au niveau de la partie entraînement, ce qui vous permet un examen plus précis du facteur de sécurité de votre unité, ce qui permet une conception optimale de l'équipement.

| Arbre de sortie | Arbre solide |

| Direction(s) de l’alésage de sortie | toute direction (horizontal, vertical vers le bas, vertical vers le haut) |

| Style de montage | Montage à semelle, montage à bride, montage sur carter |

| Taille de cadre | 15 tailles |

| Rapport de réduction | 6:1 - 658503:1 |

| Capacité | 0.2 kW - 30 kW |

| Types de moteur | Triphasé, rendement supérieur, haute efficacité, pour inverseurs, extérieur, sécurité accrue, compatible avec les normes internationals. |

±10

%

(accuracy of configured torque ±5 - ±10%)

±25

%

Adjustable range for the configured torque

0

Worry

Our Cyclo® Gearmotor provides safe, worry-free performance with built-in safety features.

Product Features

Compact

Compact Cyclo® reducer boasts a high reduction ratio, high efficiency, and a small number of parts, including a superior built-in torque sensor (spring / limit switch type, load cell type).

High Accuracy and Reliability

The sensor base consists of coiled springs or load cells, and features high accuracy and reliability. (Accuracy of configured torque ±5 - ±10%)

Allows for Economical Equipment Design

The torque limiting is applied at the drive part, allowing you a more accurate examination of your device safety factor, which makes optimal equipment design possible.

Operates During Momentary Overload

The mechanical torque detection mechanism allows for a shorter detection time compared to thermal relays, detecting overloads instantaneously.

Wide Range of Torque Adjustment

The adjustment range for configuring the torque is a wide ±25%, which means adjustments can easily be made on-site to match the actual torque of the equipment. (However, it must be within the maximum and the minimum configured torque).

Safe Unattended Operation

Built-in buzzer and indicator light in the motor operation circuit ensures a safe unattended operation. By using either the double or triple safety models, it is also possible to drive the auxiliary motor for a thickener shaft.

Combine with Other Protection Equipment

Can be combined with shear pins to achieve double or triple protection against overloads.

Break-resistant Teeth

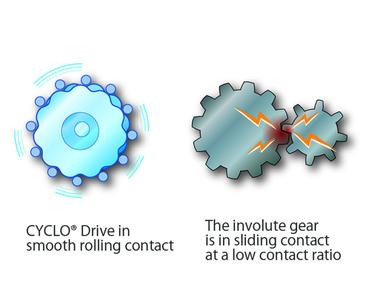

Unlike a regular involute tooth-gear, the "cycloidal disc," which is the gear for the Cyclo® Reducer, features a distinctively smooth curve.

A unique circular-arc tooth profile is also used for the internal gear. The smooth rolling contact that prevents tooth breakage results in a durable reducer with a long service life. (Some low reduction ratio models use helical gears and planetary gears.)