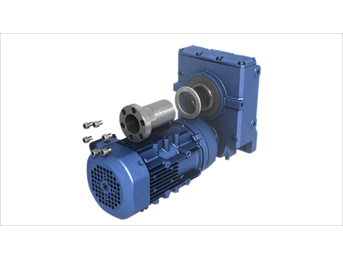

Cyclo® Helical Buddybox

Helical gearbox with Cyclo reducer input. Features keyless, Steel Taper-Grip® bushing for easy installation.

Offset parallel, helical gearbox in a rugged integral, shaft-mounted design.

- Integrated Cyclo® technology

- Keyless Taper-Grip® Bushing or Keyed Hollow Bore

- Ideal for Screw-Conveyor applications

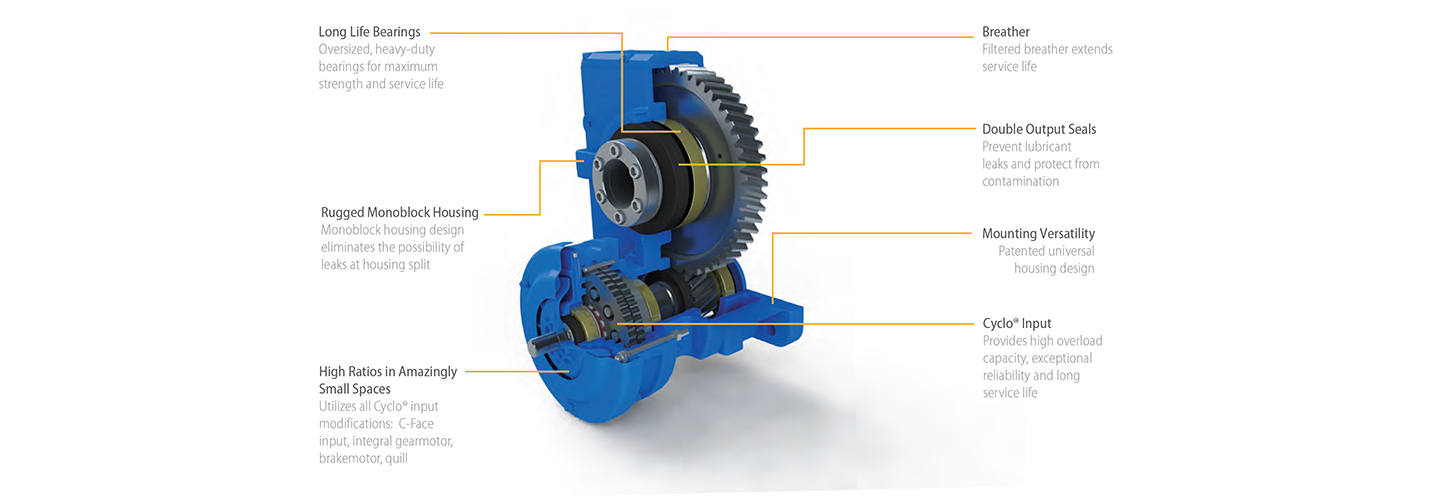

| Input | Integral gearmotor, quill and C-face adapter |

| Output | Taper-Grip® Bushing, Keyed Hollow Bore, Screw Conveyor |

| Ratios | 11:1 up to 26,000:1 and greater |

| Torque | Up to 8,565 Nm |

| Power Range | 0.1 to 30 kW |

| Mounting | Hollow Shaft, Flange, Face |

| Options | Integral Motor, C-Face |

| Motor Standards | NEMA, IEC, JIS, UL, CSA, CE |

Cyclo® HBB

Sumitomo’s Cyclo® Helical Buddybox® (Cyclo® HBB) speed reducers and gearmotors provide innovative shaft-mounted drive solutions for demanding applications. The Cyclo® HBB combines the quiet, efficient and reliable performance of the Cyclo® input with the rugged helical-gear output. The modular design provides a compact, efficient product and the most flexible range of output speed and torque combinations available.

Key Facts

CAD / Configure

Select your level of product detail:

Learn more about our CONFIGURATOR TOOL:

FAQ

Do you have questions about the Cyclo HBB? Below are some of our most commonly asked questions, or you can view our Support area under Knowledge for more frequently asked questions and answers.

What kind of torque arm do you supply? At what position should it be mounted?

The standard torque arm assembly is shown in the Dmensions section of our catalog. The torque arm should be mounted at 90 degrees to a line from the point of attachment to the reducer and the center of the output bore with up to 30 degrees plus or minus variance. It should always be mounted in tension, not compression. A bracket type torque arm is also offered as a non-stock option.

Why is a Taper-Grip® bushing used? What is its material?

The Taper-Grip® bushing is integral to the Cyclo® HBB and provides for easy mounting and removal to and from the shaft of the driven machine. Because it requires no keyway, the shaft isn't weakened and maximum torque is transmitted. With the added strength of steel, the Taper-Grip® bushing can be used in reversing and/or high start-up applications. The steel Taper-Grip® bushing can be used on all

Taper-Grip® products.

What are the thermal limitations of the Cyclo® HBB?

The Cyclo® speed reducer, by virtue of its smooth, almost frictionless operation (unlike traditional helical gears), has a thermal rating that far exceeds its mechanical capacity and all but eliminates the conventional limitations due to heat.

What are the standard input speeds?

In general terms, the speeds are 1750 and 1165 RPM. The selection tables in our catalogue are based on 1750 RPM. When other input speeds are used, the horsepower and torque ratings will vary.

What do I do if my application has particularly severe operating conditions?

The standard ratings for Cyclo® HBB are based on 10-hour daily service under conditions of uniform loads (equivalent to AGMA service factor 1.0). By following the product selection process outlined in our catalog, you will determine and apply the Service Factors to compensate for severe operating conditions.

What are service factors and how are they used?

In general, reducers and gearmotors are rated for specific conditions and operating requirements of the application by the use of AGMA-defined Service Factors. There are three AGMA load classifications for reducers: uniform (U), moderate shock (M), and heavy shock (H). Refer to our catalogue for a list of AGMA load classifications. These Service Factors are used in the product selection process to adjust for the specific conditions and operating requirements of your application.

What information do I need to get started in the selection process?

To select the proper reducer for your application, you will need to know:Application: type of driven machine

Hours of operation per day

Motor horsepower (HP) and speed (RPM)

Loading Conditions

Mounting Position

Ambient environment (altitude, dusty, chemical, explosive, water)

Ambient temperature and humidity

You must also note any special environmental factors or operation requirements. This information will be important in determining your application's service factor.

How do I select a Cyclo® HBB reducer or gearmotor?

Selection is based on the actual horsepower and/or torque requirements at the output shaft. The Cyclo® HBB speed reducer has particularly high efficiencies over a wide range of reduction ratios, which frequently permits the use of reduced input power requirements (smaller HP motor) without sacrificing output shaft torque. The selection procedures in our catalog will guide you in choosing the most efficient reducer for your application.