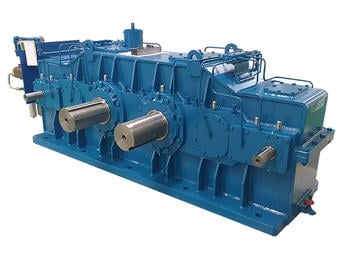

Special Paramax: Drop-In Reducers

Paramax Special Gearboxes:

- Customizable

- Interchangeable ("Drop-in")

- Engineering Excellence

- Premium Performance

- Worldwide Support

| Mounting Options : | Horizontal, Vertical and Upright mounting |

| Ratio Range: | 1: 1,25 - 1:630 |

| Shaft Arrangement: | Paralell, Right-Angle |

| Power Range: | 3,7 - 3.729 kW |

| Torque Range: | 2.600 - 740.000 Nm |

Documents

Download literature and Special and Drop-in Units Brochure

What is the largest reduction ratio actually available with a Cyclo®?

Theoretically any combination is available by multiplying single reduction ratios: 6, 8, 11, 13, 15, 17, 21, 25, 29, 35, 43, 51, 59, 71, 87, and 119:1.

In the Cyclo® catalog, there are more than two reducer types indicated for one motor input capacity. Which reducer model should I choose?

Selection should be made based on required Service factor. The Service Factor value depends on the load characteristics and operation time for the customer’s application.

What is the allowable input speed of the Cyclo®?

Generally, Cyclo® Drives allow for input at 3600r/min for up to 3HP, 6:1 to 87:1 ratio. For more than 3HP, it varies depending on frame size and reduction ratio. Many Cyclo models can accept input speeds of up to 3,600 RPM. However, the maximum allowable input speed is dependent upon the model number and the reduction ratio.

Are mounting bolts included with the Cyclo®?

Mounting bolts are not included. Refer to the maintenance manual for mounting bolt specifications.

Can the Cyclo® Drive be mounted vertically?

Models having an "N" after the nomenclature symbol "C (Cyclo)," are universal mounting models that can be mounted in any direction . However, when there is an "H (horizontal)," "V (vertical with slow speed shaft downward)" or "W (vertical type with slow speed shaft upward)," after the "C," the unit cannot be mounted in any direction other than the one specified.

What is the principle of Cyclo® technology?

Cyclo® is a type of internal planetary gear. The planetary gear has cycloidal-shaped teeth. All torque-transmitting parts roll, not grind. Unlike the normal involute teeth with limited contact points, a Cyclo has two-thirds of its reduction components in contact at all times. Multiple teeth share the load, so therefore the Cyclo® is not susceptible to tooth breakage.

The service factor of the Cyclo® reducer is generally higher than the traditional gearmotor. Why?

This is because Cyclo has a high teeth engagement rate. Since the Cyclo gearing has two-thirds of its reduction components in contact at all time, it can withstand higher shock loads and is more stable than traditional involute gearing.

What are the standard Cyclo® input speeds?

In general terms, the speeds are 1750 and 1165 RPM. The selection tables in our catalog are based on 1750, 1165, 870, 580, and 50 RPM. When non-standard input speeds are used, the kilowatt (or horsepower) and torque ratings also vary.

What information do I need to select a Cyclo® speed reducer or gearmotor?

To select the proper reducer for your application, you need to know: Application: type of driven machine

Hours of operation per day

Motor horsepower (HP) and speed (RPM)

Mounting position

Ambient environment (altitude, dusty, chemical, explosive, water)

Ambient temperature and humidity

You must also note any special environment factors or operational requirements. This information will be important in determining your application's service factor.

What thermal capacity limitations does the Cyclo® have?

The Cyclo speed reducer, by virtue of its smooth, almost frictionless operation (unlike traditional helical gears), has a thermal rating that far exceeds its mechanical capacity, and all but eliminates the conventional limitations due to heat.