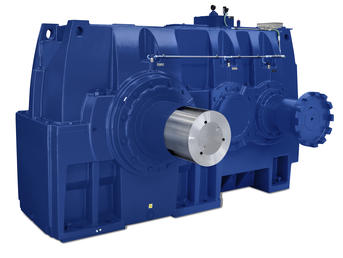

Hansen P4 Multistage - Horizontal

Dedicated Gearbox series to measure all horizontal applications

- Specific horizontal housing - available in 19 sizes from 6 to 1100 kNm output Torque.

- Parallel and right Angle - 2/3/4 stage gearboxes with a wide range of reduction ratios.

- Service friendly with split plane, inspection cover and maintenance-free sealing system.

- Reliable product series allowing flexible customization and options upon request.

- Powerful Hansen P4 gear geometry for low noise and vibration levels.

| Number of Sizes | 19 |

| Housing type | Specific housings for horizontal applications |

| Gears | Helical and Bevel helical (in accordance with AGMA) |

| Stages | 2, 3 or 4 stage |

| Reduction Ratios | 6.3:1 to 630:1 and special ratio's upon request |

| Nominal output torque | from 6 to 1100 kNm |

| Input speed | up to 1800 rpm |

| Shaft type | Solid or hollow low speed shaft |

| Lubrication | Splash lubrication |

Key Product Facts

1.100

kNm

Maximum Nominal output Torque (and even larger upon request)

19

sizes

Parallel and Right Angle gearboxes

2/3/4

stages

A wide range of reduction ratios

Advantages of Hansen P4 Horizontal Series

Dedicated Horizontal Housing

Stepped housing, better load distribution & easy access to mounting feet

Split Housing & Large Inspection Cover

Maintenance-friendly, easy inspection without oil drainage

Powerfull Gear Geometry

For maximum load capacity, minimum losses & lower noise levels

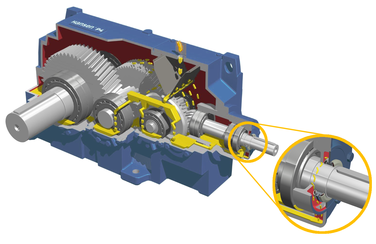

Maintenance-Free Sealing Systems

Oil-lock at the high speed shaft designed to keep the oil in and dirt out

Never a Dry Start-up

Centralized oil filling guarantees initial oil lubrication at start-up. During operation, optimized splash lubrication with oil flow through the bearings

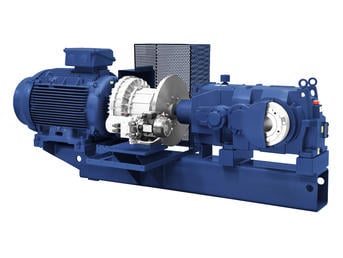

Instruments & Accessories

Condition monitoring instruments, Cooling devices & Complete Drive Packages (including base plates or lantern housings, motors, couplings,...)

Filters

What are backstops?

Backstops are safety devices and have to be inspected at regular time intervals. The periodical inspection is to be carried out by authorized personnel. The frequency of the inspection depends on the type of application. Please refer to the P4 service manual for recommended inspection intervals

What type of lubrication method does the P4 use?

Hansen P4 units use one of the following systems:

- Splash Lubrication (standard with horizontal shaft gear units for speeds between 750 and 1800RPM at the high speed shaft. Gears and output shaft bearings are lubricated by immersion in the oil bath. Oil splash from gears fill the oil pockets in the housing, assuring gravity circulation lubrication of the bearings via channels in the housing and covers.)

- Force Feed Lubrication (all rotating elements above oil bath level are lubricated by a gear pump forcing the oil through pressure lines. Forced feed lubrication is available as circulation lubrication or pressure lubrication.